In the healthcare sector, the precision of ultrasound imaging is crucial for accurate patient diagnoses. As reliance on advanced ultrasound equipment becomes commonplace, maintaining these devices to ensure peak performance is essential.

Regular and thorough maintenance is essential to extend the lifespan of ultrasound machines. Many people have become oblivious to the significance of proactive actions in sustaining the operation of this sophisticated equipment as a result of the move to digital technology. This article sheds light on when and why thorough maintenance checks are vital for the various components of ultrasound machines.

Importance Of Maintenance

Ultrasound equipment, such as probes, transducers, displays, control panels, and CPUs, experiences regular wear and tear. Consistent maintenance is imperative, irrespective of the expertise of radiologists and sonographers. Collaborating with a dependable maintenance service provider not only facilitates smoother operations but also contributes to significant long-term cost savings. Adhering to Original Equipment Manufacturer (OEM) standards in the maintenance of ultrasound technology reassures healthcare professionals of reliable performance.

Probe/Transducer

The probe or transducer is arguably the most vulnerable component of an ultrasound machine, constantly exposed to various elements during its operation. Its critical job is sending ultrasonic waves across the body, which create pictures by reflecting off dense structures. Maintenance checks are required regularly to address wear and tear concerns that might jeopardize accuracy. Sonographers should meticulously examine the transducer for imperfections like breaks, cuts, or swelling of the lens material. By adhering to proper handling practices and addressing deformities promptly, healthcare providers can maximize the lifespan of transducers, typically lasting up to seven years with diligent care.

CPU (Central Processing Unit)

The CPU, sometimes known as the "brain" of the ultrasound machine, is in charge of translating ultrasonic waves into visual information for transmission to the display. This sophisticated procedure entails extensive computations and quick data processing, culminating in real-time, precise representations of diverse tissue densities in the body. To maintain optimal functionality, regular checkups and maintenance are imperative. Investing in a maintenance service contract with knowledgeable professionals, familiar with the intricacies of ultrasound systems, can not only extend the life of the CPU but also provide invaluable on-call support, minimizing downtime and potential disruptions in patient care.

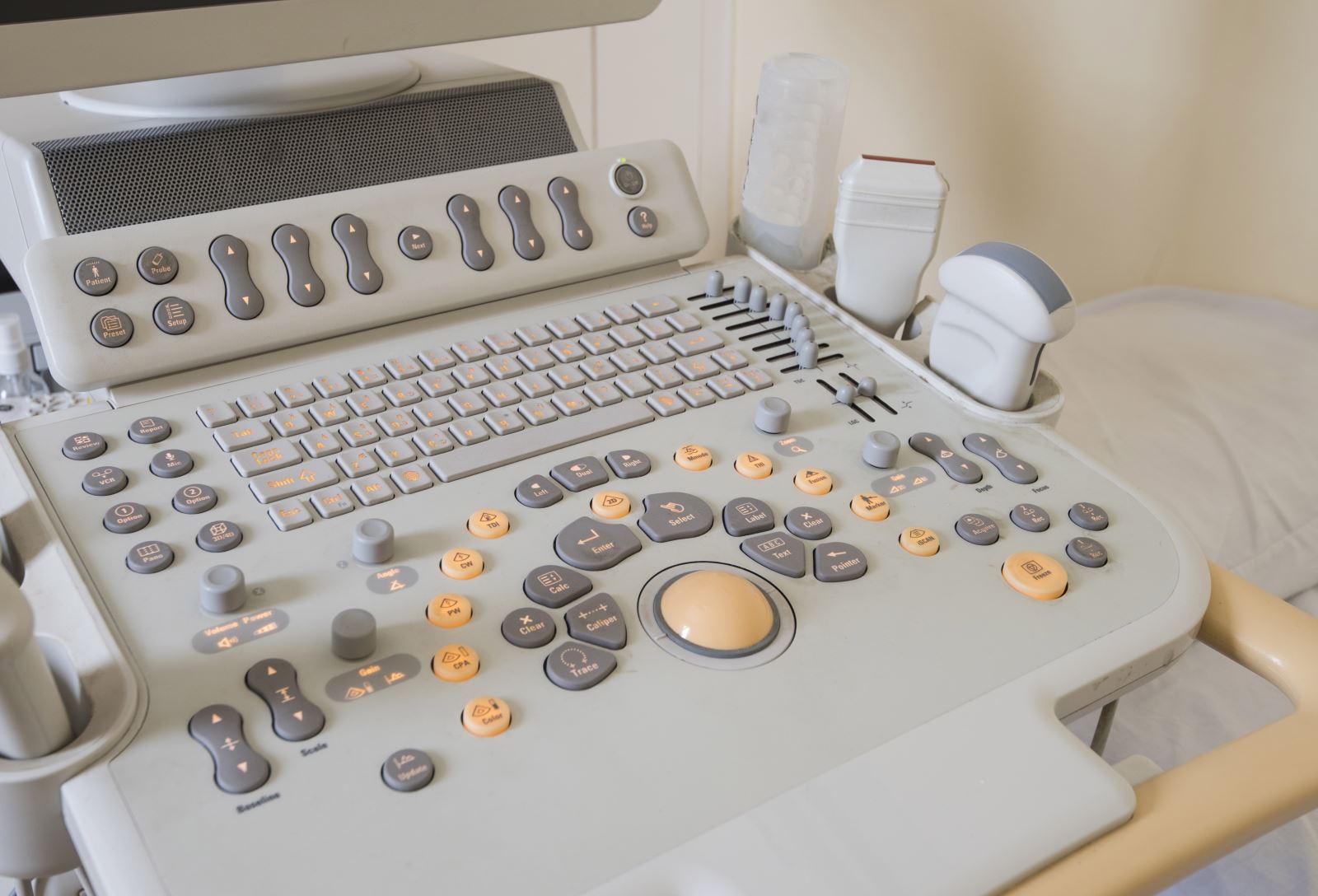

Control Panel

The control panel serves as the interface between the sonographer and the ultrasound machine's computer, playing a crucial role in guiding the imaging process. Regular maintenance of the control panel is essential for guaranteeing visual clarity, inspecting for damaged components and keys on the console, and maintaining the trackball. Any compromise in the functionality of the control panel can lead to flawed imaging, creating challenges for sonographers in their diagnostic tasks. Healthcare practitioners may ensure smooth and precise ultrasound exams by prioritizing routine inspections and resolving difficulties as they arise.

Philips Affiniti 70 Components

Monitor

The ultrasound machine's monitor is the window through which sonographers visualize and analyze scanned images. Ensuring the proper functioning of the monitor is essential for accurate diagnoses. Regular maintenance involves checks for video functionality, calibration to focus on specific objects and adherence to OEM-recommended standards. Sonographers rely on the monitor to detect deformities and anomalies, making it critical to delivering high-quality healthcare. Through meticulous maintenance, healthcare providers can uphold the monitor's integrity, enabling sonographers to scrutinize and interpret images with confidence.

Ultrasound Equipment Suppliers

HDD Storage and Printers

Components like HDD storage and printers are the data management backbone of ultrasound machines. Regular maintenance checks involve verifying power supply, peripheral arrangements, and routine upkeep for printers, including mechanical checks and ink cartridge replacements. These components are critical in preserving accuracy and flexibility as healthcare technology becomes more mobile, with cloud solutions enabling remote access to patient data. By embracing modern solutions while maintaining traditional components, healthcare providers can ensure that ultrasound data remains accessible, secure, and precise, even in remote locations.

Conclusion

Finally, prioritizing frequent ultrasound equipment maintenance inspections is critical for accurate diagnosis and effective healthcare delivery. If you are looking for new ultrasound equipment, look no further than Xity! We specialize in ultrasound equipment including ultrasound probes, ultrasound machines, ultrasound parts, etc. Please consider us as your trusted ultrasound equipment supplier and get top-quality products!

English

English

Русский

Русский