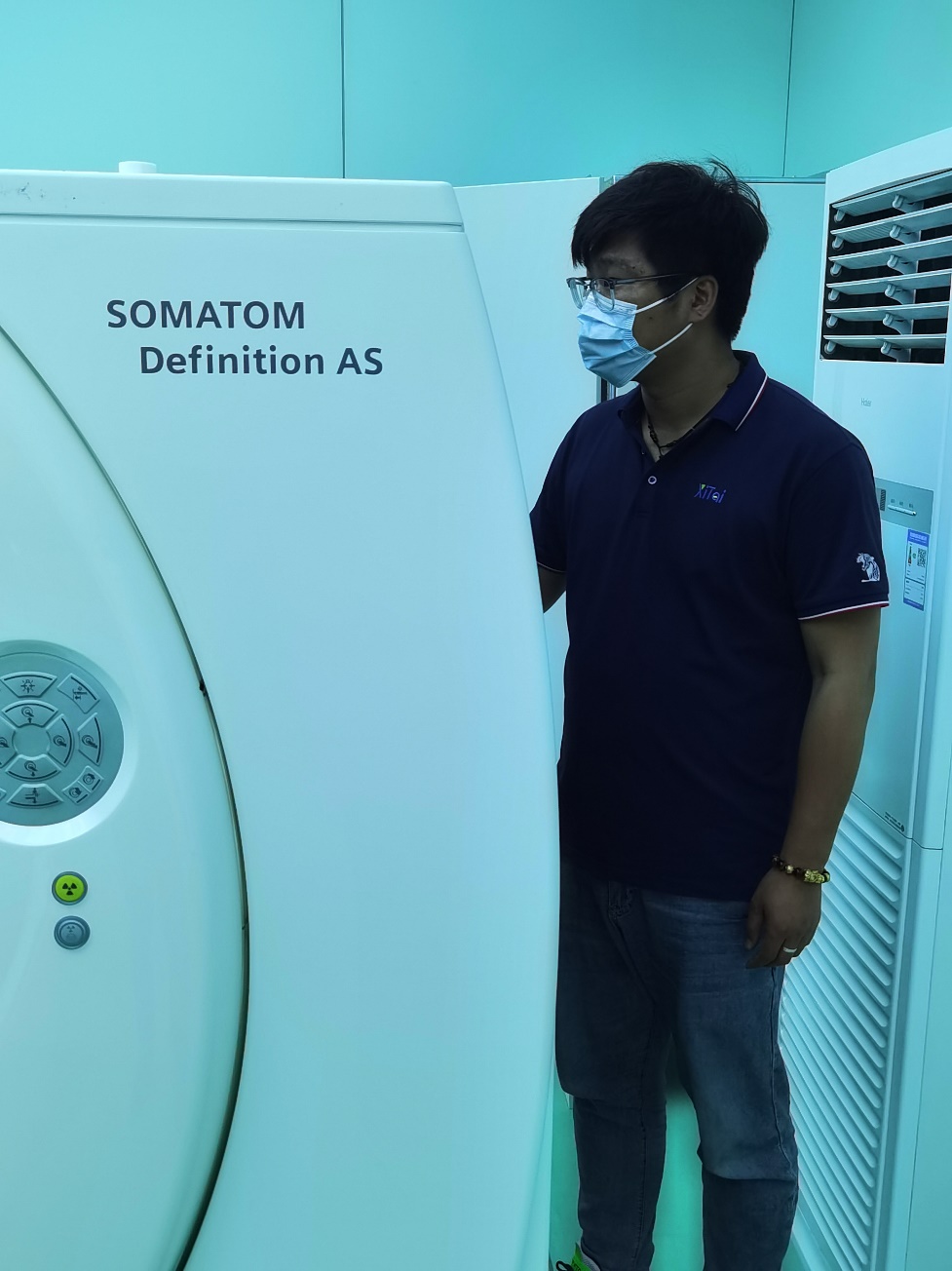

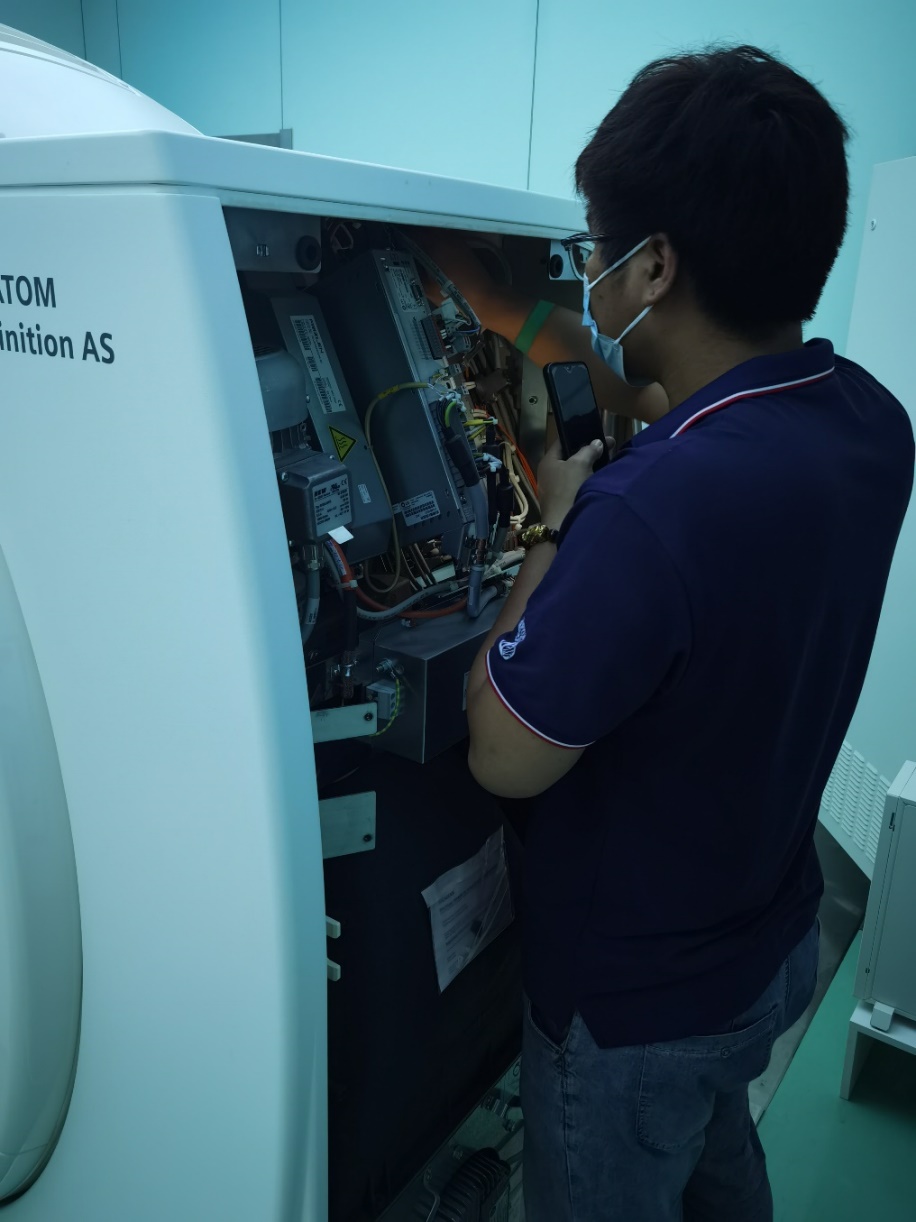

CT team of Xity Medical has fifteen years of maintenance experience, and the engineers have original training certificates from GE, Philips and other manufacturers. In the work of maintaining CT equipment, engineers provide suggestions on product repair and image optimization. They establish product files, manage and verify important information such as equipment information and backup and regularly organize and audit maintenance logs, work logs, etc. They formulate reasonable procurement plans, and quickly retrieve required spare parts.

Maintenance process of CT machine:

1. Although the CT machine is regularly maintained, inspected and calibrated, it is still difficult to avoid failures. It is very necessary to develop a complete set of maintenance procedures for rapid troubleshooting.

After a fault occurs, you should first judge whether the operator's operation is correct, and whether the ambient temperature and humidity are appropriate (the temperature between 20 degrees Celsius and 23.8 degrees Celsius is suitable. If the temperature is too high, it is not conducive to the heat dissipation of the machine, and it is easy to cause damage to the electrical components of the machine. The humidity is more suitable at 58% RH. If it is lower than 30% RH, it will be too dry and easy to generate static electricity and spark. If it is higher than 75%. RH, it is easy to cause machine corrosion, short circuit and electrical parameter changes). It also depends on whether there is too much dust and whether there is any abnormal sound. For example, we eliminated the problem of the cooling tube of the X-ray tube rubbing against the casing through the abnormal noise, and the problem of the large inductance in the high-speed starter breaking away from the fixed box. Look at the computer part of the start-up self-test process is correct.

2. If the system can complete the startup process, it can be seen that the above-mentioned parts are initialized normally. If it can be operated, run the fault description and fault diagnosis program, check the error record, and combine the fault phenomenon to analyze and determine which of the following five categories the fault belongs to:Power supply, computer hardware and software and operation control part failure; no X-ray failure; mechanical failure; data acquisition and reconstruction failure; image output failure.

English

English

Русский

Русский